Intelligent industrial robotic arms are no longer limited to traditional manufacturing, but have gradually penetrated into various industries and become a key technology for production and service innovation in many fields.

In the process of intelligent transformation of the global manufacturing industry, industrial robotic arms have become an important tool for improving production efficiency, optimizing product quality and reducing production costs. From traditional automation equipment to today’s intelligent manufacturing partners, the technological evolution and wide application of robotic arms are leading a revolution in the manufacturing industry.

With the rapid development of technologies such as artificial intelligence, big data, cloud computing and the Internet of Things, robotic arms not only play a core role in traditional manufacturing, but also show broad application prospects in various fields such as medical care, logistics and services. This article will explore the technological evolution, industry applications and important position of industrial robotic arms in promoting the global intelligent manufacturing process.

Part I The Evolution of Industrial Robotic Arms

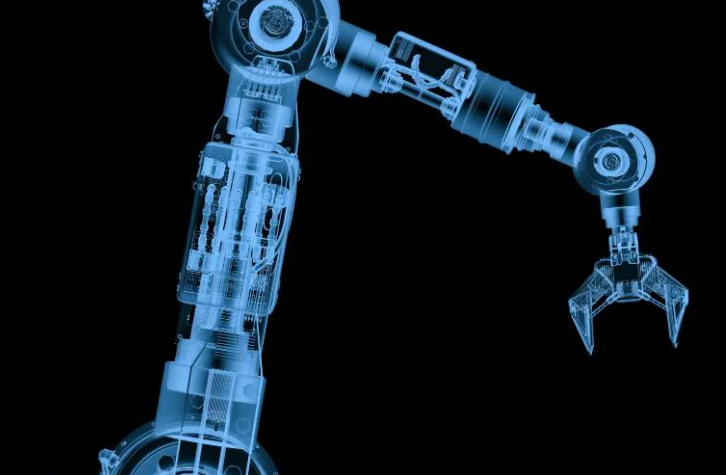

The history of industrial robotic arms can be traced back to the 1950s. At that time, robotic arms were mainly used in the fields of automobile manufacturing and heavy industry, responsible for completing some simple and highly repetitive tasks, such as welding, assembly and handling. They complete fixed process work through simple programming, but due to the limitations of hardware and software technology, robotic arms have great limitations in accuracy, flexibility and adaptability. Nevertheless, with the advancement of computer science and sensor technology, robotic arms have gradually experienced major technological breakthroughs and continuously expanded their application areas. Entering the 1980s, with the improvement of control technology and computer performance, the accuracy and flexibility of robotic arms have been significantly improved, and they can perform more complex production tasks. By the beginning of the 21st century, with the rise of artificial intelligence, machine learning and big data technology, robotic arms have ushered in a more leapfrog development. These new technologies enable robotic arms to not only complete simple repetitive tasks, but also have the ability to make autonomous decisions, real-time perception and self-learning, and gradually develop into intelligent and efficient production tools. At present, with the continuous maturity of computer vision technology and deep learning algorithms, the capabilities of robotic arms in visual perception, path planning and action execution have reached unprecedented heights. Through high-precision sensors and intelligent algorithms, robotic arms can identify changes in the working environment in real time and make adaptive adjustments. This technological advancement enables robotic arms to maintain efficient and precise working performance in highly complex and dynamically changing production environments.

Part II Comprehensive coverage from manufacturing to services

Intelligent industrial robotic arms are no longer limited to traditional manufacturing, but have gradually penetrated into various industries and become a key technology for production and service innovation in many fields. However, manufacturing is one of the most widely used areas for industrial robotic arms. With the continuous upgrading of production technology, robotic arms play an indispensable role in the production lines of many industries such as automobiles, electronics, home appliances, and food. In automobile manufacturing, robotic arms are responsible for completing highly repetitive and dangerous tasks such as welding, spraying, and handling, which greatly improves production efficiency and reduces safety hazards. In the manufacturing process of electronic products, the high precision and flexibility of robotic arms can complete extremely delicate assembly tasks. For example, robotic arms can achieve millimeter-level positioning through precise control during the installation of electronic components and chips, thereby ensuring the quality and reliability of products. For high-precision and difficult production tasks, robotic arms show unparalleled advantages. With the improvement of automation, production lines are no longer fixed, and robotic arms can provide support in flexible production modes. This means that robotic arms can not only adjust their working methods according to production needs, but also quickly adapt to different production needs. This flexibility makes robotic arms not only suitable for mass production, but also provides efficient solutions for small-batch customized production.

In the field of logistics, intelligent robotic arms also show great application potential. Especially in automated warehousing and sorting systems, robotic arms have become one of the key technologies to improve logistics efficiency. Many large e-commerce platforms, such as Amazon and Alibaba, have deployed robotic arms in their warehouses to achieve efficient and automated sorting, handling and packaging of goods. In modern warehouses, robotic arms can quickly sort, handle and stack items. Through visual recognition and image processing technology, robotic arms can accurately identify different goods and automatically handle them. This efficient operation method not only improves the space utilization of warehouses, but also greatly improves the speed and accuracy of cargo handling. In addition, with the application of 5G and Internet of Things technologies, robotic arms can achieve real-time connection and data sharing with other devices. This makes the entire logistics system more intelligent and precise in scheduling and monitoring, thereby optimizing the overall logistics process. The medical industry is another highlight of the application of robotic arm technology. Especially in the field of surgical robots, the precise operation of robotic arms can help doctors complete more complex and minimally invasive surgeries, reduce patients’ risks and accelerate the recovery process. In the field of rehabilitation therapy, robotic arms also have great application potential. Through robot-assisted rehabilitation equipment, patients can conduct more personalized training and improve rehabilitation effects. The robotic arm can adjust the training intensity and provide real-time feedback according to the patient’s recovery progress, thereby helping patients recover faster. In the service industry, the application of robotic arms is gradually expanding, especially in the fields of catering, hotels and retail. In the catering industry, robot chefs have entered some high-end restaurants and fast food restaurants, and can automatically complete tasks such as cutting and frying ingredients. With the help of robotic arms, restaurants can improve production efficiency and ensure the quality and consistency of dishes. In the hotel industry, the application of robotic arms is more extensive. Robotic front desks, cleaning robots and food delivery robots are gradually becoming part of hotel services. These robotic arms can reduce labor costs and improve work efficiency while providing standardized services.

Part 4 Rapid Growth and Technological Innovation in the Global Market

According to data from the International Federation of Robotics (IFR), the global industrial robotic arm market is experiencing rapid growth, especially in China, where the robotic arm market has become one of the most active markets in the world. The “Smart Manufacturing 2025″ strategy promoted by the Chinese government has provided policy support for the development of robotic arm technology and promoted breakthroughs in technological innovation and market share of domestic robots. At the same time, as production costs continue to decline, more and more small and medium-sized enterprises can afford robotic arm systems, thereby promoting the popularization of automated and intelligent production. In addition, the development of collaborative robot (Cobot) technology has provided more flexible and economical automation solutions for small and medium-sized enterprises, further expanding the market share of robotics technology. At the same time, the integration of emerging technologies such as 5G, artificial intelligence, and the Internet of Things has provided a broader space for the intelligence of robotic arms. Through 5G technology, robotic arms can achieve real-time data transmission and remote control, further improving production efficiency and operation accuracy. Through the Internet of Things, robotic arms can collaborate efficiently with other equipment in the factory to promote the intelligent optimization of the entire production process.

Post time: Jan-10-2025