As an emerging product of industrial robots, robotic arms have shown broad application prospects in the fields of industry, medicine, military and even space.

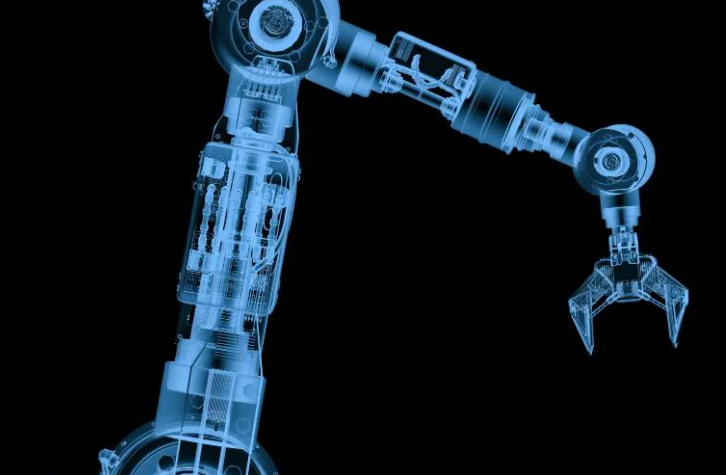

1. Definition and characteristics of robotic arms A robotic arm is a mechanical device that can be automatic or manually controlled, usually used to grab or move objects. It can achieve automatic control, repeatable programming and multi-degree-of-freedom (axis) movement. The robotic arm completes various work tasks by making linear movements along the X, Y, and Z axes to reach the target position.

2. The relationship between robotic arms and industrial robots A robotic arm is a form of industrial robot, but industrial robots are not limited to robotic arms. An industrial robot is an automated device that can accept human commands, run according to pre-programmed programs, and even act according to the principles and guidelines formulated by artificial intelligence technology. Robotic arms are most widely used in the field of industrial robots, but industrial robots also include other forms, such as mobile robots, parallel robots, etc.

3. Application fields of robotic arms Industrial field: Robotic arms play an important role in industrial production, such as automobile manufacturing, electronics and electrical, metal processing and other industries. They can complete tasks such as handling, welding, assembly, spraying, etc., and improve production efficiency and quality. Medical field: In medical surgery, robotic arms are used to precisely control surgical instruments, reduce surgical risks and increase the success rate of surgery. In addition, robotic arms can also be used for rehabilitation therapy and assisting the lives of disabled people. Military and space fields: Robotic arms also play an important role in military and space exploration. They can be used to perform dangerous tasks, conduct space repairs and scientific experiments, etc.

4. Development trend of robotic armsIntelligent: With the development of artificial intelligence technology, robotic arms will have higher perception and autonomous decision-making capabilities. They can continuously optimize their working methods through learning, improve work efficiency and accuracy. High precision: With the continuous advancement of manufacturing technology, the accuracy of robotic arms will continue to improve. This will enable them to complete more delicate and complex tasks and meet higher quality production needs. Multifunctionality: Future robotic arms will have more functions, such as visual recognition, voice recognition, etc. This will enable them to better adapt to various working environments and task requirements. Collaborative operation: Robotic arms will work more closely with other robots and humans. Through information sharing and collaborative control, they will jointly complete more complex production tasks.

5. Challenges and opportunities of robotic armsChallenges: The development of robotic arms faces challenges such as technical bottlenecks, high costs, and ethics. It is necessary to continuously break through technical difficulties, reduce costs, and strengthen research and supervision on ethics. Opportunities: With the transformation and upgrading of the manufacturing industry and the increase in intelligent demand, robotic arms will usher in a broader development prospect. They will play a greater role in various fields and promote the progress and development of society.

In summary, as an emerging product of industrial robots, robotic arms have broad application prospects and development potential. With the continuous advancement of technology and the continuous expansion of the market, robotic arms will play a more important role in various fields.

Post time: Jan-07-2025