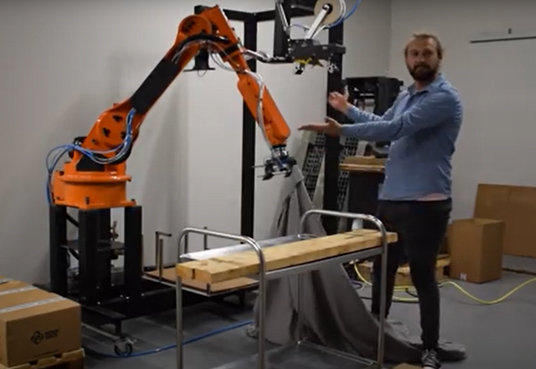

The packaging robot is an advanced, intelligent, and highly automated mechanical equipment, which mainly includes intelligent detection systems, packaging manipulators, handling manipulators, stacking systems and control systems, etc. It replaces traditional manual operations and realizes multiple links such as product transportation, sorting, detection, packaging, loading and unloading. It has the advantages of high work efficiency and precise operation, which can effectively save manpower, time and other costs, and has been widely used in the food industry. Classification of packaging robots

Product packaging generally has many forms. According to the shape, material, weight and cleanliness requirements of the object, the packaging procedure is relatively complicated. At present, there are mainly the following types of robots for this packaging process:

Bagging robot: The bagging robot is a fixed rotary type with a 360-degree rotation body. The robot completes the transportation, bag opening, metering, filling, bag sewing and stacking of the packaging bag. This is a highly intelligent packaging robot. Boxing robot: Similar to the bagging robot, the boxing of metal and glass packaging containers is generally completed by a rigid box robot. There are two types of mechanical and air suction types for grabbing the boxed packaging. It can move as a whole. Grab or adsorb the package, and then send it to the packaging box or pallet at the designated position. It has the function of automatic direction and position adjustment, and can realize no unloading and direction adjustment without box (pallet). This type of robot is a relatively mature robot with a wide range of applications. Such as beverages, beer, etc.

Filling robot: This is a robot that measures, caps, presses (screws) and identifies after the packaging container is filled with liquid materials. It has the functions of no feeding without bottles, no feeding without caps, broken bottle alarm and automatic rejection. In the past, many of our liquid materials were mainly filled with the local function of this robot-the manipulator was installed on the production line. Now, this robot is directly configured at the rear of the material production host to realize its automatic filling. Filling robots are divided into soft packaging and hard packaging. The hard packaging (bottling) filling robot is analyzed here.

Packaging conveying robot: This type of robot in the packaging industry mainly refers to the robot used for plastic bottle packaging and conveying. It uses power and special components to realize the conveying of bottles (empty bottles), quickly outputs and arranges the packaging bottles in the bottle barrel, and then gives a specific (direction, size) force. Make the bottle body accurately pass through the parabola route in the air to reach the filling workpiece. This robot changes the traditional bottle conveying mechanism. It speeds up the conveying speed and reduces the conveying space. It is a packaging robot with a new concept. It uses aerodynamics and special mechanical components to achieve its conveying operation.

Advantages of packaging robots

1. Accuracy of production The robot arm is fixedly installed on a solid machine base, and the axes of the multi-axis robot are rotated by servo motors and gears, which ensures that the robot can flexibly and freely determine the workstation within the working radius.

2. Ease of operation The system controls the robot, mechanical gripper and conveyor belt through PLC, and the system is equipped with a special touch screen to display information during the production process. The system adopts an advanced human-machine interface, and operators can easily modify parameters and select programs on the interface.

3. Production flexibility The robot’s gripper is installed in the center of the flange. It can be designed as a fixed tool or replaced with different professional grippers through an automatic hand-changing device to adapt to special tasks. The robot can replace and install different grippers according to the needs of the actual production process to meet the needs of flexible production. The robot can also cooperate with the laser visual inspection system to identify the type of workpiece and help the robot locate the workpiece.

Features of packaging robots

1. Strong applicability: When the size, volume, shape and external dimensions of the products produced by the enterprise change, only a slight modification is needed on the touch screen, which will not affect the normal production of the enterprise. The change of traditional mechanical palletizers is quite troublesome or even impossible. 2. High reliability: The packaging robot can always maintain the same state during repeated operations, and there will be no subjective interference similar to that of humans, so its operation reliability is relatively high.

3. High degree of automation: The operation of the packaging robot relies on program control, without human participation, with a high degree of automation, saving a lot of labor.

4. Good accuracy: The operation control of the packaging robot is precise, and its position error is basically below the millimeter level, with very good accuracy.

5. Low energy consumption: Usually the power of a mechanical palletizer is around 26KW, while the power of a packaging robot is around 5KW, which greatly reduces the operating costs of customers.

6. Wide range of applications: The packaging robot is widely used. It can complete multiple operations such as grabbing, handling, loading and unloading, and stacking.

7. High efficiency: The working speed of the packaging robot is relatively fast and there is no time interruption, so its working efficiency is relatively high.

8. Small footprint: The packaging robot can be set up in a narrow space and can be used effectively, which is conducive to the layout of the production line in the customer’s factory and can leave a larger warehouse area.

Nowadays, the packaging industry has gradually entered the era of automation. As the most competitive embodiment of automation technology, industrial robots are very suitable for repetitive, fast, accurate and dangerous processes. The application of packaging robots can not only reduce costs, but also bring more efficient flexibility. Not only packaging industrial robots, many companies choose to use different types of industrial robots because of their flexibility and reliability. In the future, industrial robots will replace more traditional equipment and become one of the important driving forces for the development of various fields.

Post time: Nov-20-2024