I believe everyone has heard of the robot. It often shows its prowess in movies, or is Iron Man’s right-hand man, or accurately operates various complex instruments in precision technology factories. These imaginative presentations give us a preliminary impression and curiosity about the robot. So what is an industrial manufacturing robot?

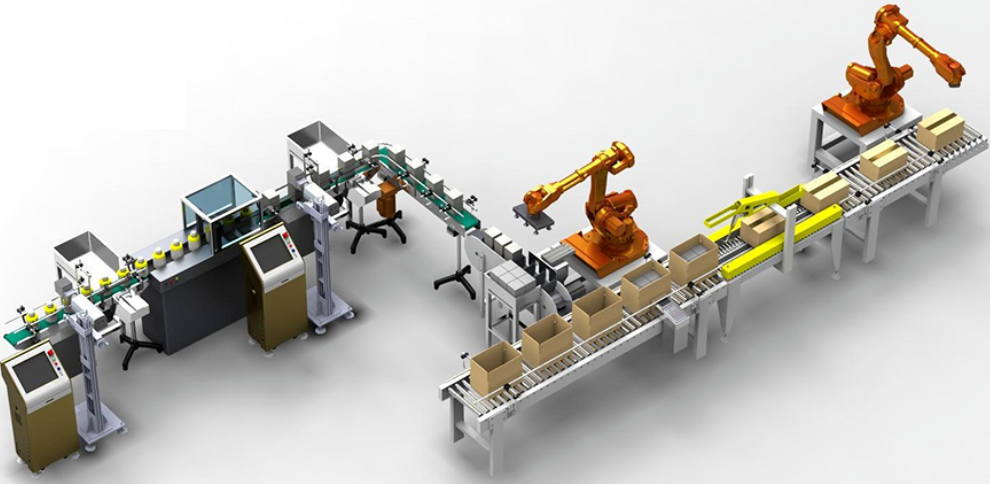

An industrial manufacturing robot is a mechanical device that can automatically perform tasks. It can imitate some of the movements of human arms and perform operations such as material handling, parts processing, and product assembly in an industrial production environment. For example, in an automobile manufacturing workshop, the robot can accurately grab automobile parts and install them to the specified position. Industrial manufacturing robots are generally powered by drive devices such as motors, cylinders, and hydraulic cylinders. These drive devices move the joints of the robot under the command of the control system. The control system is mainly composed of a controller, a sensor, and a programming device. The controller is the “brain” of the robot, which receives and processes various instructions and signals. The sensor is used to detect the position, speed, force, and other status information of the robot. For example, during the assembly process, a force sensor is used to control the assembly force to avoid damage to parts. The programming device can be a teaching programmer or computer programming software, and the motion trajectory, action sequence and operating parameters of the manipulator can be set through programming. For example, in welding tasks, the motion path and welding parameters of the manipulator welding head, such as welding speed, current size, etc., can be set through programming.

Functional features:

High precision: It can accurately position and operate, and the error can be controlled at the millimeter or even micron level. For example, in the manufacture of precision instruments, the manipulator can accurately assemble and process parts.

High speed: It can quickly complete repetitive actions and improve production efficiency. For example, in an automated packaging production line, the manipulator can quickly grab products and put them into packaging containers.

High reliability: It can work stably for a long time and reduce errors caused by factors such as fatigue and emotions. Compared with manual labor, in some harsh working environments, such as high temperature, toxicity, and high intensity, the manipulator can work more continuously.

Flexibility: Its work tasks and movement modes can be changed through programming to adapt to different production needs. For example, the same manipulator can perform high-speed material handling in the peak production season and fine assembly of products in the off-season.

What are the application areas of industrial manufacturing manipulators?

Automobile Manufacturing Industry

Parts Handling and Assembly: On automobile production lines, robots can efficiently carry large parts such as engines and transmissions and accurately assemble them to the chassis of the car. For example, a six-axis robot can install a car seat to a specified position on the car body with extremely high precision, and its positioning accuracy can reach ±0.1mm, greatly improving assembly efficiency and quality. Welding Operation: The welding work of the car body requires high precision and speed. The robot can weld the various parts of the body frame together using spot welding or arc welding technology according to a pre-programmed path. For example, an industrial manufacturing robot can complete the welding of a car door frame in 1-2 minutes.

Electronic and Electrical Industry

Circuit Board Manufacturing: During the production of circuit boards, robots can mount electronic components. It can accurately mount tiny components such as resistors and capacitors on circuit boards at a speed of several or even dozens of components per second. Product Assembly: For the assembly of electronic products, such as mobile phones and computers, robots can complete tasks such as shell assembly and screen installation. Taking mobile phone assembly as an example, the robot can accurately install components such as display screens and cameras into the body of the mobile phone, ensuring the consistency and high quality of product assembly.

Mechanical processing industry

Loading and unloading operations: In front of CNC machine tools, stamping machines and other processing equipment, the robot can undertake the task of loading and unloading. It can quickly grab the blank material from the silo and send it to the workbench of the processing equipment, and then take out the finished product or semi-finished product after processing. For example, when the CNC lathe processes shaft parts, the robot can complete the loading and unloading operation every 30-40 seconds, which improves the utilization rate of the machine tool. Part processing assistance: In the processing of some complex parts, the robot can assist in the flipping and positioning of parts. For example, when processing complex molds with multiple faces, the robot can flip the mold to the appropriate angle after one process is completed to prepare for the next process, thereby improving the efficiency and accuracy of part processing.

Food and beverage industry

Packaging operations: In the packaging link of food and beverages, the robot can grab the product and put it into the packaging box or packaging bag. For example, in a beverage canning production line, the robot can grab and pack 60-80 bottles of beverages per minute, and can ensure the neatness and standardization of the packaging.

Sorting operation: For food sorting, such as grading and sorting of fruits and vegetables, the robot can sort according to the size, weight, color and other characteristics of the product. In the sorting process after the fruit is picked, the robot can identify fruits of different quality grades and place them in different areas, which improves the sorting efficiency and product quality.

Logistics and warehousing industry

Cargo handling and palletizing: In the warehouse, the robot can carry goods of various shapes and weights. It can take the goods off the shelves or stack the goods on pallets. For example, large logistics and warehousing robots can carry goods weighing several tons, and can stack the goods into neat stacks according to certain rules, which improves the space utilization of the warehouse. Order sorting: In environments such as e-commerce logistics, the robot can sort the corresponding goods from the shelves of the warehouse according to the order information. It can quickly scan product information and accurately place the products on the sorting conveyor belt, speeding up order processing.

What are the specific effects of the application of industrial manufacturing manipulators on enterprise production efficiency?

Improve production speed

Fast repetitive operation: Industrial manufacturing manipulators can perform repetitive work at a very high speed without fatigue and reduced efficiency like manual operation. For example, in the assembly process of electronic components, the manipulator can complete dozens or even hundreds of grabbing and installation actions per minute, while manual operation may only be completed a few times per minute. Taking mobile phone production as an example, the number of screens installed per hour using manipulators can be 3-5 times more than manual installation. Shorten production cycle: Since the manipulator can work 24 hours a day (with proper maintenance) and has a fast conversion speed between processes, it greatly shortens the production cycle of the product. For example, in automobile manufacturing, the efficient operation of the manipulator in the body welding and parts assembly links has reduced the assembly time of a car from dozens of hours to more than ten hours now.

Improve product quality

High-precision operation: The operation accuracy of the manipulator is much higher than that of manual operation. In precision machining, the robot can control the machining accuracy of parts to the micron level, which is difficult to achieve with manual operation. For example, in the production of watch parts, the robot can accurately complete the cutting and grinding of tiny parts such as gears, ensuring the dimensional accuracy and surface finish of the parts, thereby improving the overall quality of the product.

Good quality stability: Its action consistency is good, and the product quality will not fluctuate due to factors such as emotions and fatigue. In the process of drug packaging, the robot can accurately control the dosage of the drug and the sealing of the package, and the quality of each package can be highly consistent, reducing the defective rate. For example, in food packaging, after using the robot, the product loss rate caused by unqualified packaging can be reduced from 5% – 10% in manual operation to 1% – 3%.

Optimize production process

Automated process integration: The robot can seamlessly connect with other automated equipment (such as automated production lines, automatic warehousing systems, etc.) to optimize the entire production process. On the production line of electronic products, the robot can closely integrate the production, testing and assembly of circuit boards to achieve automated continuous production from raw materials to finished products. For example, in a complete computer motherboard production workshop, the robot can coordinate various processing equipment to complete a series of processes from the production of printed circuit boards to chip installation and welding, reducing the waiting time and human intervention in the intermediate links. Flexible task adjustment: The robot’s work tasks and work order can be easily adjusted through programming to adapt to different production needs and product changes. In clothing manufacturing, when the style changes, only the robot program needs to be modified to adapt it to the cutting, sewing assistance and other tasks of the new style of clothing, which improves the flexibility and adaptability of the production system.

Reduce production costs

Reduce labor costs: Although the initial investment of the robot is high, in the long run, it can replace a large amount of manual labor and reduce the company’s labor cost expenditure. For example, a labor-intensive toy manufacturing company can reduce 50%-70% of assembly workers after introducing robots for the assembly of some parts, thereby saving a lot of money in labor costs. Reduce scrap rate and material loss: Because the robot can operate precisely, it reduces the generation of scrap caused by operating errors, and also reduces material loss. During the process of picking up and trimming injection molded products, the robot can accurately grab the products to avoid product damage and excessive waste of scraps, reducing the scrap rate by 30% – 50% and material loss by 20% – 40%.

Post time: Jan-21-2025