From the perspective of architecture, the robot can be divided into three parts and six systems, of which the three parts are: mechanical part (used to realize various actions), sensing part (used to perceive internal and external information), control part (Control the robot to complete various actions). The six systems are: human-computer interaction system, control system, drive system, mechanical mechanism system, sensory system, and robot-environment interaction system.

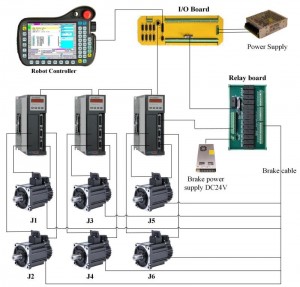

(1) Drive system

To make the robot run, it is necessary to install a transmission device for each joint, that is, each degree of freedom of motion, which is the drive system. The driving system can be hydraulic transmission, pneumatic transmission, electric transmission, or a comprehensive system combining them; it can be direct drive or indirect drive through mechanical transmission mechanisms such as synchronous belts, chains, wheel trains, and harmonic gears. Due to the limitations of pneumatic and hydraulic drives, except for special occasions, they no longer play a dominant role. With the development of electric servo motors and control technology, industrial robots are mainly driven by servo motors.

(2) Mechanical structure system

The mechanical structure system of an industrial robot consists of three parts: a base, an arm, and an end effector. Each part has several degrees of freedom, forming a multi-degree-of-freedom mechanical system. If the base is equipped with a walking mechanism, a walking robot is formed; if the base does not have a walking and waist turning mechanism, a single robot arm is formed. The arm generally consists of the upper arm, lower arm and wrist. The end effector is an important part directly mounted on the wrist. It can be a two-fingered or multi-fingered gripper, or a paint spray gun, welding tools and other operating tools.

(3) Sensory system

The sensory system consists of internal sensor modules and external sensor modules to obtain meaningful information on internal and external environmental states. The use of smart sensors improves the level of mobility, adaptability and intelligence of robots. The human sensory system is extremely dexterous for perceiving the information of the external world. However, for some special information, sensors are more effective than the human sensory system.

(4) Robot-environment interaction system

The robot-environment interaction system is a system that realizes the mutual connection and coordination between industrial robots and equipment in the external environment. Industrial robots and external equipment are integrated into a functional unit, such as processing and manufacturing units, welding units, assembly units, etc. Of course, multiple robots, multiple machine tools or equipment, multiple parts storage devices, etc. can also be integrated into one functional unit to perform complex tasks.

(5) Human-computer interaction system

The human-computer interaction system is a device that enables the operator to participate in the control of the robot and communicate with the robot, for example, the standard terminal of the computer, the command console, the information display board, the danger signal alarm, etc. The system can be summed up into two categories: instruction given device and information display device.

(6) Control system

The task of the control system is to control the actuator of the robot to complete the prescribed movement and function according to the robot’s operating instruction program and the signal fed back from the sensor. If the industrial robot does not have information feedback characteristics, it is an open-loop control system; if it has information feedback characteristics, it is a closed-loop control system. According to the control principle, the control system can be divided into program control system, adaptive control system and artificial intelligence control system. According to the form of control motion, the control system can be divided into point control and trajectory control.

Post time: Dec-15-2022