990 Milling PLC Macro CNC Controller

Product Parameters

Application: Lathe and Turning Center,CNC Boring Machine, CNC wood working machine, CNC Milling machinery, CNC drilling machinery, and especially automatic equipment

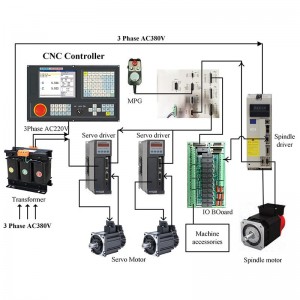

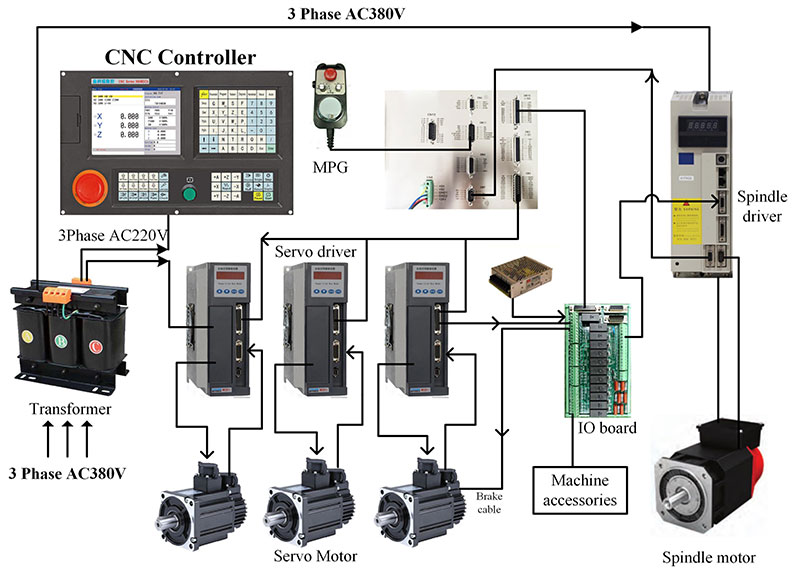

Axis: 1-4 axis

Machinery Test Report: Provided.

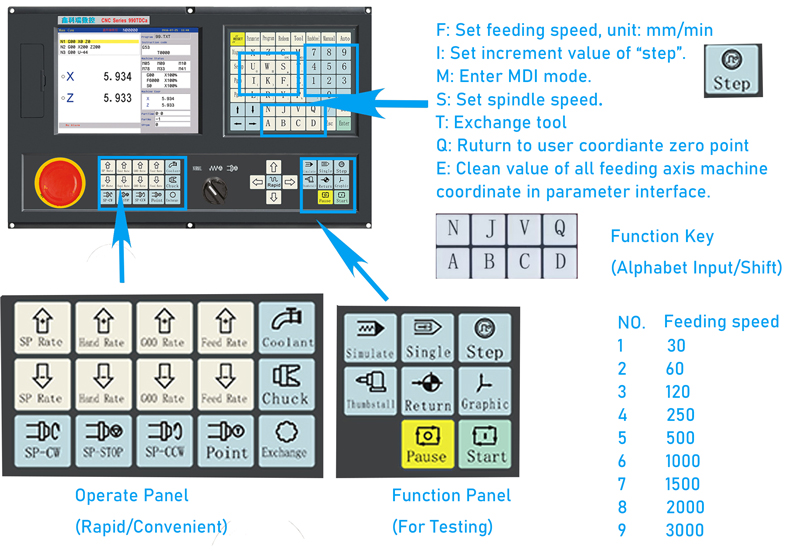

Function: Support ATC, Macro function, and PLC displayer

Core Components: PLC, CNC, Macro program, CNC controller.

CPU: ARM(32bits)+DSP+FPGA.

Port: 56input 32output

Weight: 8KG

User Store Room: 128Mb

Interface:USB+RS232 Communction Port.

Supply Ability:10000 Set/Sets per Month.

Warranty:2 Years

Product Features

1.Never Crush the machine, the system with memorial function (Abosolute feature)

2.Needn't install hard limit with this 3 axis control wood drilling and milling machine and back to the zero point (Abosolute feature)

3.Adapt bus modbus technology, ARM + DSP + FPGA technology

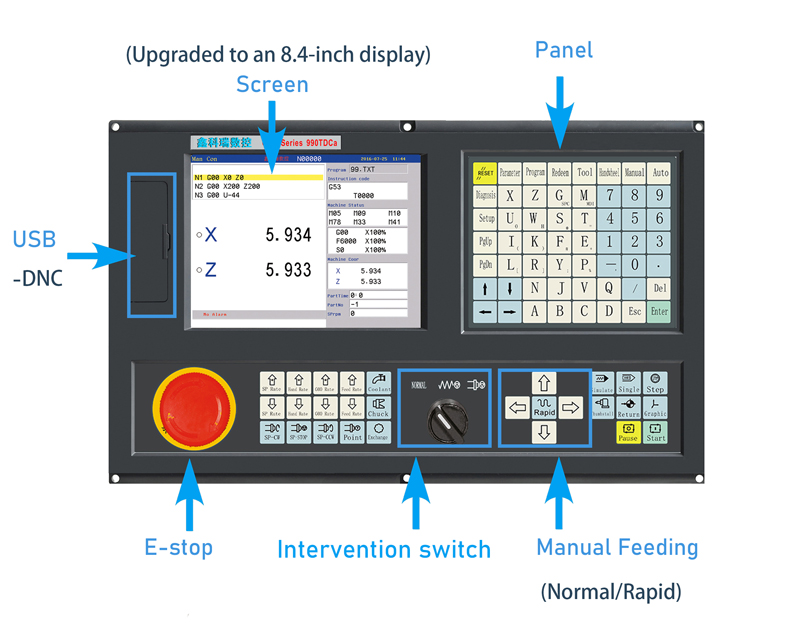

4.USB and RS232 port, DNC function of USB (NEW)

5.Network remote technology and could diagnose the system online (NEW)

6.User's storage is 128M and could be infinite number of program (NEW)

7.Abosolute type of motor (17bits multi circle) controlling technology (NEW)

8.The most moving rapid speed is 300m/min, processing speed reaches 0.01 ~ 30m/min (NEW)

9.The cycle of interpolation is 2ms, controlling accuracy is 0.1um (NEW)

10.All closed loop with grating ruler control and the accuracy is <2um (NEW)

11.Preread the short line program to satisfy with high-speed engraving and cutting (NEW)

12.Intelligent Man-Machine dialog interface (NEW)

13.NEWKer's CNC controller also supports the application of various special machines, such as grinding machines, planers, boring machines, drilling machines, forging machines, gear hobbing machines, etc. The controller can also be secondary developed. Support personalized customization and design.

Function Advantage

1. simple and clear parameter, unnecessary to look up manual.

2. open PLC, can be edit online or offline according to needs.

3. Open Macro program, available for flexible application and further development.

4. Customerization dialog, make process easier.

5. Open OPC port, available for remote monitor and control.

Customer Application Cases