990 2 axis 3 axis 4 axis Lathe CNC Controller Closed Loop

Parameter

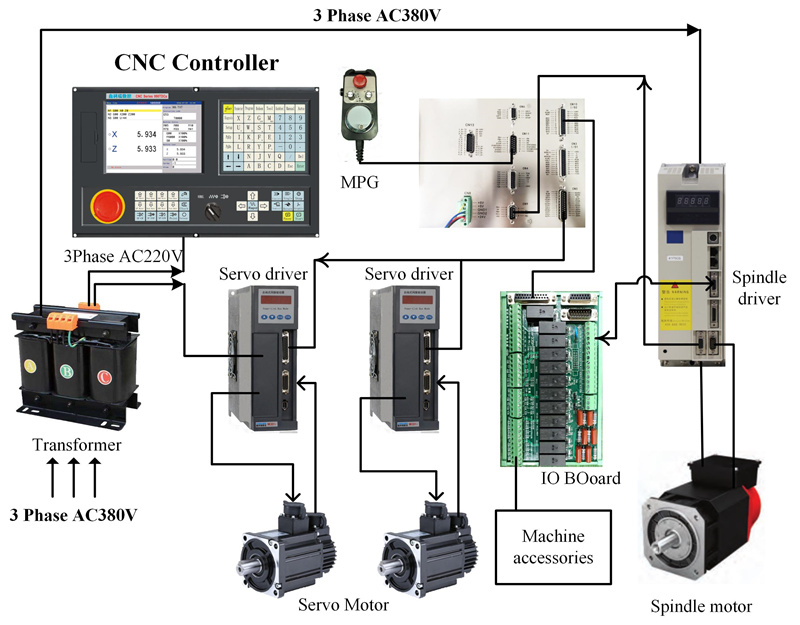

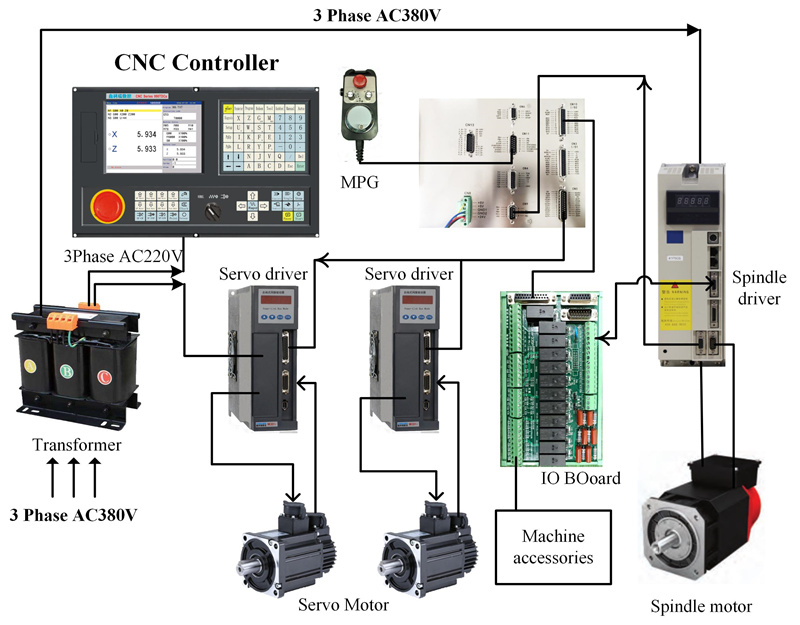

1) adopt modbus technology , and ARM, DSP , and FPGA , very high performance.

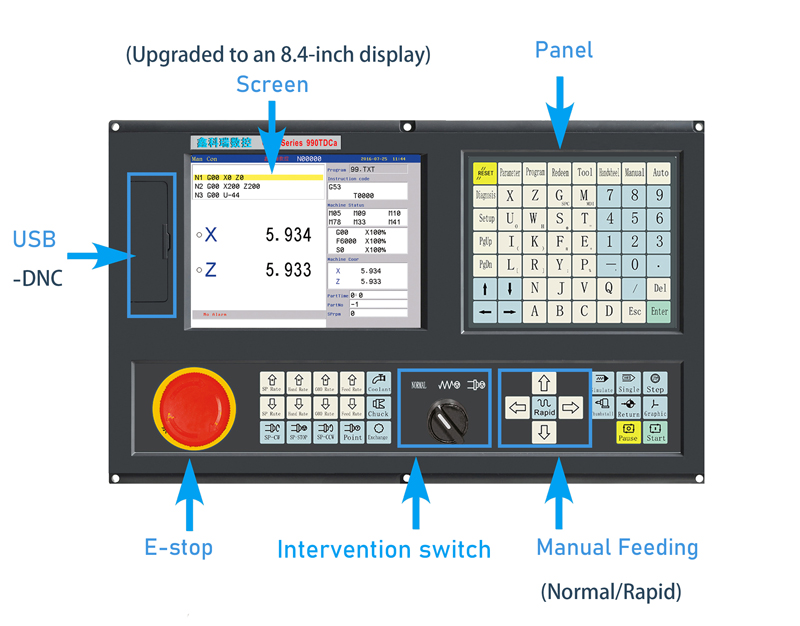

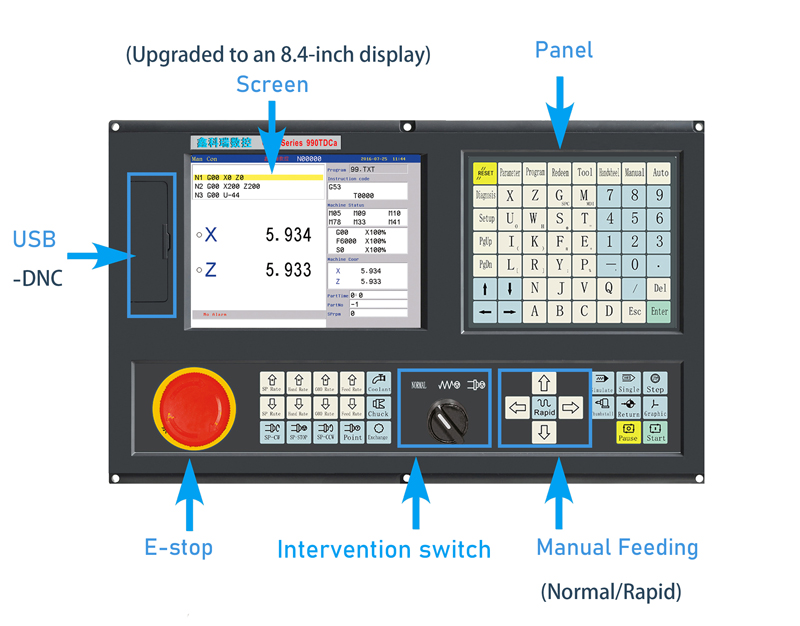

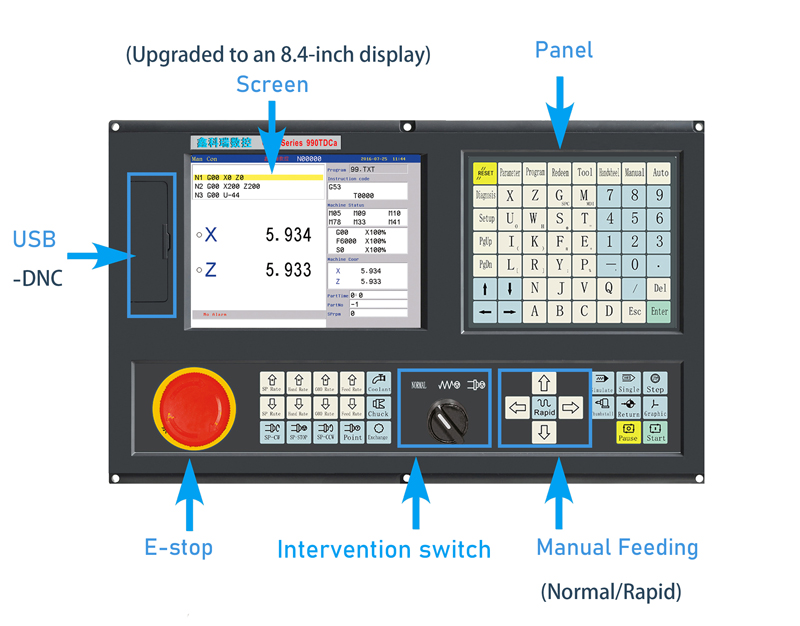

2) Vertical CNC Lathe controller with USB and 2-5 axis more beautiful interface

3) 128Mb user store room, not limit for programming quantity.

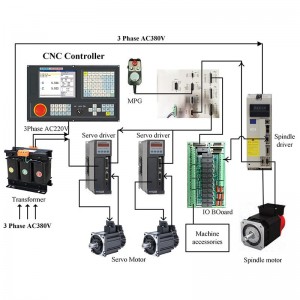

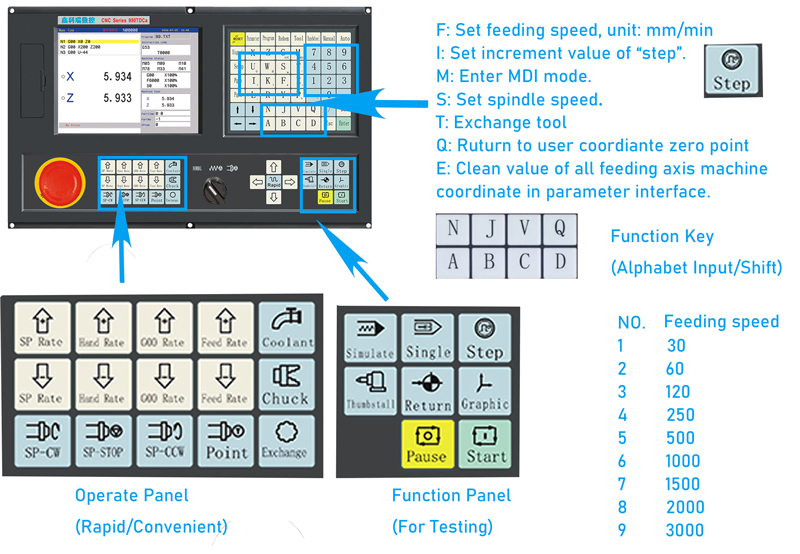

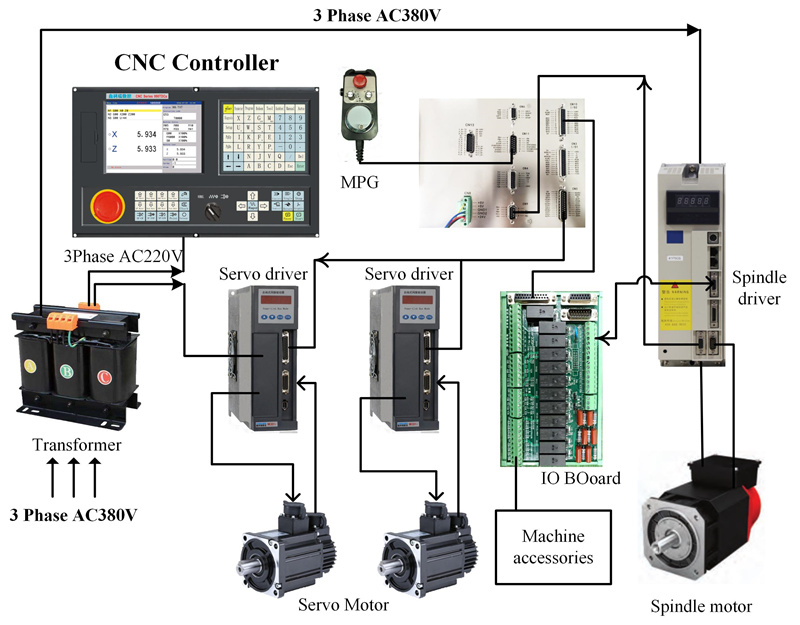

4) 640x480 8 inch real colour LCD displayer, I/O 56X32

5) with addtional operation panel and MPG, supply power

6) Pulse Output Frequency: 5MHz, Max speed 300m/min, progressing speed 0.01-150m/min

7) USB movable U disc copy interface.

8) RS232 interface.U flash DNC function

9) Spindle servo speed control/spindle frequency convertion speed control.

10) Manual pulse generator.

11) PLC programming and macro function

12) English menu, program and interface, full screen edition

13) able to work with absolutely encoder motor , support the tool magazine function such as: umbrella type, line type, disc type etc.

14)PLC FUNCTION:

The refresh cycle: 8ms

PLC program download by USB interface

PLC program can be customized edited

V/Os: 40*24 1/Os, 24*24 I/Os can be edit freely

15)SAFETY FUNCTION:

Emergency stop

Hardware travel limit

Software travel limit

Data restoring and recovering

User-defined alarm hint

16) General G-code operation,low learning cost.

17) User-centric interface,easy to use.

18) Open PLC, can be edit online or offline according to needs

19) Open Macro program, available for flexible application and fur-ther development.

Product Features

It comes to milling and turning on standard machines as well as functions for easy automation of grinding machines

The NEWKer CNCs are very easy to operate. CNC data are quickly and easily transferred via USB and RS232 interfaces on the operator panel front

NEWKer 990 series is perfectly adapted for use in standard machines and provides optimum support for turning and milling technology.

The G-Tech technology variant provides grinding machine manufacturers with a perfect platform on which to design grinding machines - It also supports cylindrical and surface grinding machines

Parameter

1) adopt modbus technology , and ARM, DSP , and FPGA , very high performance.

2) Vertical CNC Lathe controller with USB and 2-5 axis more beautiful interface

3) 128Mb user store room, not limit for programming quantity.

4) 640x480 8 inch real colour LCD displayer, I/O 56X32

5) with addtional operation panel and MPG, supply power

6) Pulse Output Frequency: 5MHz, Max speed 300m/min, progressing speed 0.01-150m/min

7) USB movable U disc copy interface.

8) RS232 interface.U flash DNC function

9) Spindle servo speed control/spindle frequency convertion speed control.

10) Manual pulse generator.

11) PLC programming and macro function

12) English menu, program and interface, full screen edition

13) able to work with absolutely encoder motor , support the tool magazine function such as: umbrella type, line type, disc type etc.

14)PLC FUNCTION:

The refresh cycle: 8ms

PLC program download by USB interface

PLC program can be customized edited

V/Os: 40*24 1/Os, 24*24 I/Os can be edit freely

15)SAFETY FUNCTION:

Emergency stop

Hardware travel limit

Software travel limit

Data restoring and recovering

User-defined alarm hint

16) General G-code operation,low learning cost.

17) User-centric interface,easy to use.

18) Open PLC, can be edit online or offline according to needs

19) Open Macro program, available for flexible application and fur-ther development.

Product Features

It comes to milling and turning on standard machines as well as functions for easy automation of grinding machines

The NEWKer CNCs are very easy to operate. CNC data are quickly and easily transferred via USB and RS232 interfaces on the operator panel front

NEWKer 990 series is perfectly adapted for use in standard machines and provides optimum support for turning and milling technology.

The G-Tech technology variant provides grinding machine manufacturers with a perfect platform on which to design grinding machines - It also supports cylindrical and surface grinding machines

Parameter

1) adopt modbus technology , and ARM, DSP , and FPGA , very high performance.

2) Vertical CNC Lathe controller with USB and 2-5 axis more beautiful interface

3) 128Mb user store room, not limit for programming quantity.

4) 640x480 8 inch real colour LCD displayer, I/O 56X32

5) with addtional operation panel and MPG, supply power

6) Pulse Output Frequency: 5MHz, Max speed 300m/min, progressing speed 0.01-150m/min

7) USB movable U disc copy interface.

8) RS232 interface.U flash DNC function

9) Spindle servo speed control/spindle frequency convertion speed control.

10) Manual pulse generator.

11) PLC programming and macro function

12) English menu, program and interface, full screen edition

13) able to work with absolutely encoder motor , support the tool magazine function such as: umbrella type, line type, disc type etc.

14)PLC FUNCTION:

The refresh cycle: 8ms

PLC program download by USB interface

PLC program can be customized edited

V/Os: 40*24 1/Os, 24*24 I/Os can be edit freely

15)SAFETY FUNCTION:

Emergency stop

Hardware travel limit

Software travel limit

Data restoring and recovering

User-defined alarm hint

16) General G-code operation,low learning cost.

17) User-centric interface,easy to use.

18) Open PLC, can be edit online or offline according to needs

19) Open Macro program, available for flexible application and fur-ther development.

Product Features

It comes to milling and turning on standard machines as well as functions for easy automation of grinding machines

The NEWKer CNCs are very easy to operate. CNC data are quickly and easily transferred via USB and RS232 interfaces on the operator panel front

NEWKer 990 series is perfectly adapted for use in standard machines and provides optimum support for turning and milling technology.

The G-Tech technology variant provides grinding machine manufacturers with a perfect platform on which to design grinding machines - It also supports cylindrical and surface grinding machines