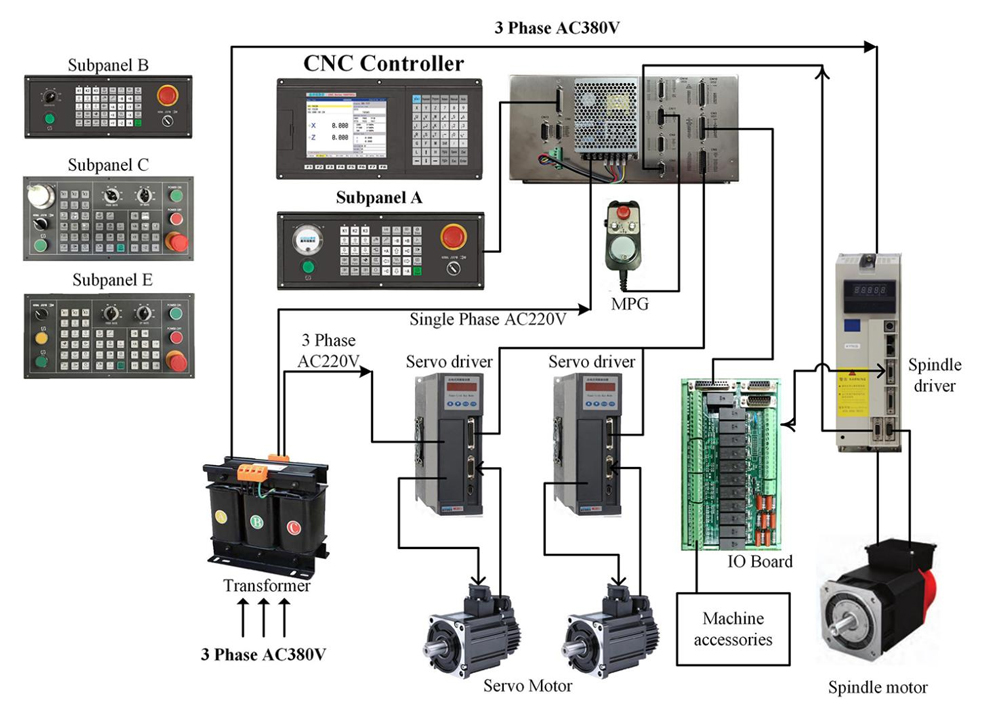

2-5 axis Lathe Controller Dual Channel System

Product Parameters

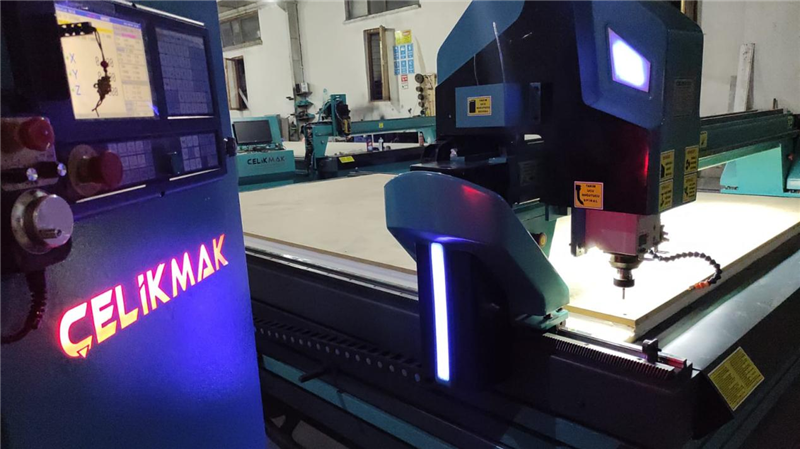

Application: Lathe and Turning Center, CNC Boring Machine, CNC wood working machine, CNC Milling machinery, CNC drilling machinery, and especially automatic equipment

Axis: 1-10axis

Machinery Test Report: Provided.

Function: Support ATC, Macro function, and PLC displayer

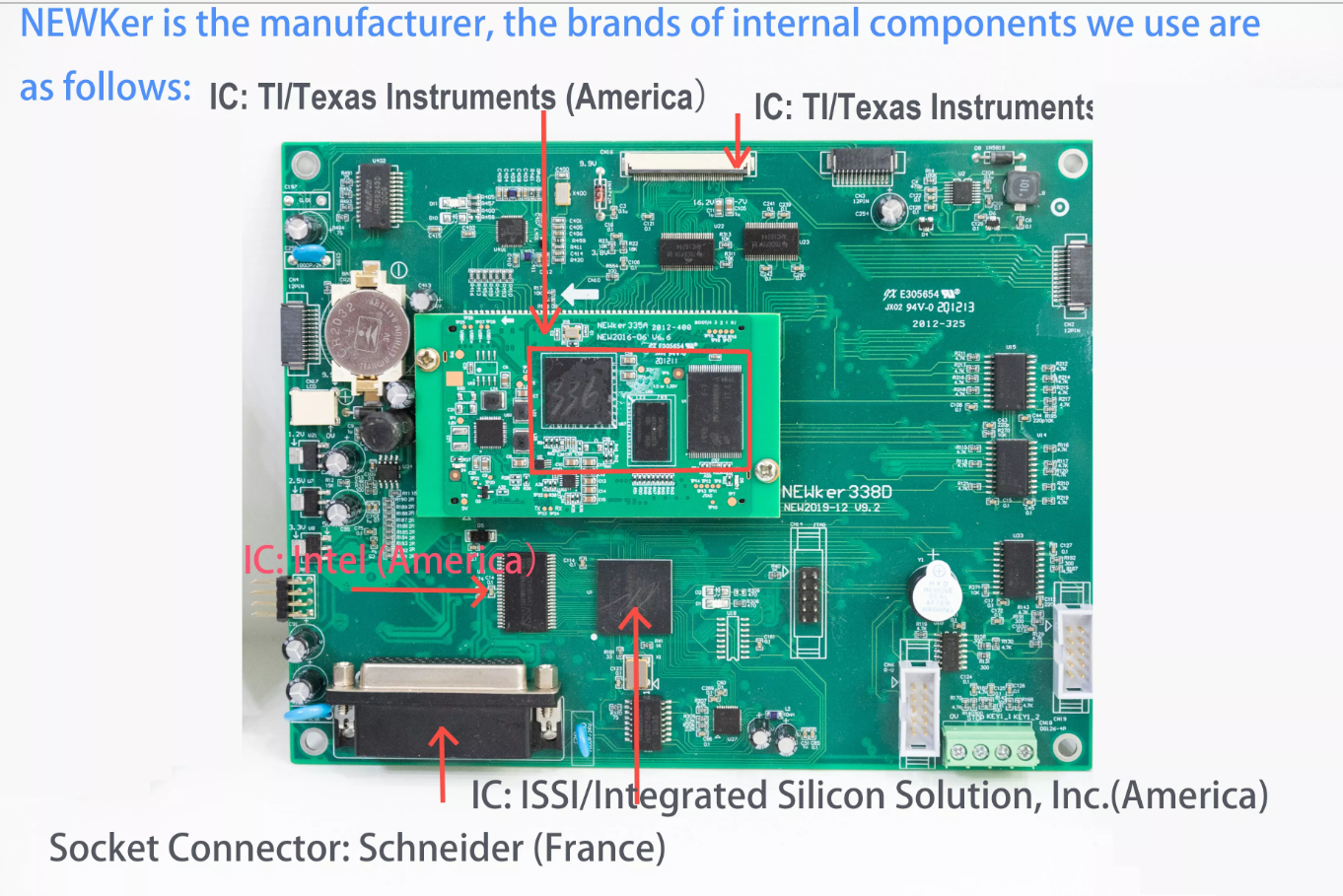

Core Components: PLC, CNC, Macro program, CNC controller.

CPU: ARM(32bits)+DSP+FPGA.

Port: 56input 32output

Weight: 8KG

User Store Room: 128Mb

Interface:USB+RS232 Communction Port.

Supply Ability:10000 Set/Sets per Month.

Warranty:2 Years

Parameter details(G code shows)

1. Locate rapidly: G00

2. Straight line interpolation: G01

3. Arc interpolation: G02/03

4. Cycle of cutting cyliner or cone: G90

5. Cycle of cutting end face: G94

6. cycle of cutting thread: G92

7. Fixed cycle of tapping: G93

8. Cycle of rough cut in excircle: G71

9. Cycle of rough cut at end face: G72

10. Cycle of closed cut: G73

11. Cycle of drill deep hole at end face: G74

12. Cycle of cutting groove with external diameter: G75

13. Cycle of cutting compound thread: G76

14. Cycle of program: G22,G800

15. Local coordinate system: G52

16. Detect the instruction of skip: G31,G311

17. Pole coordinate: G15, G16

18. Metrical/Imperial programme: G20,G21

19. Set coordinate, offset: G184,G185

20. Workpiece coordinate system: G54~G59

21. Tool radius C: G40, G41, G42

22. Accurate locating/continuous path process: G60/G64

23. Feeding mode: G98,G99

24. Backing to start point of program: G26

25. Backing to the fixed point: G25, G61, G60

26. Backing to the datum point: G28

27. Suspend: G04

28. Macro Program: G65, G66, G67

29. Auxiliary function: S, M, T

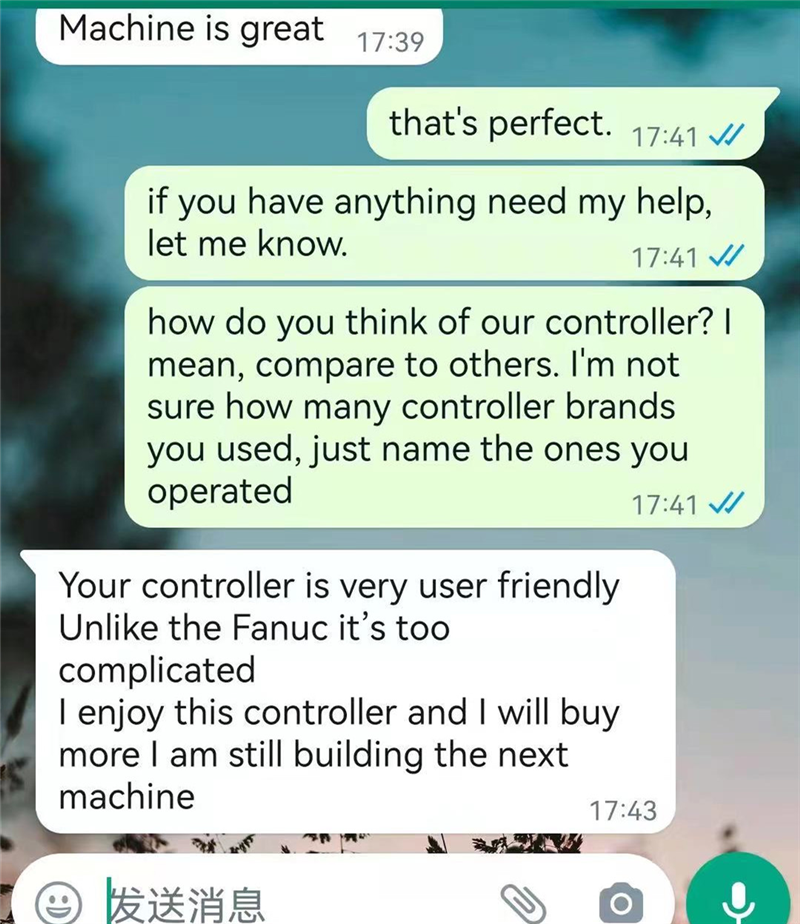

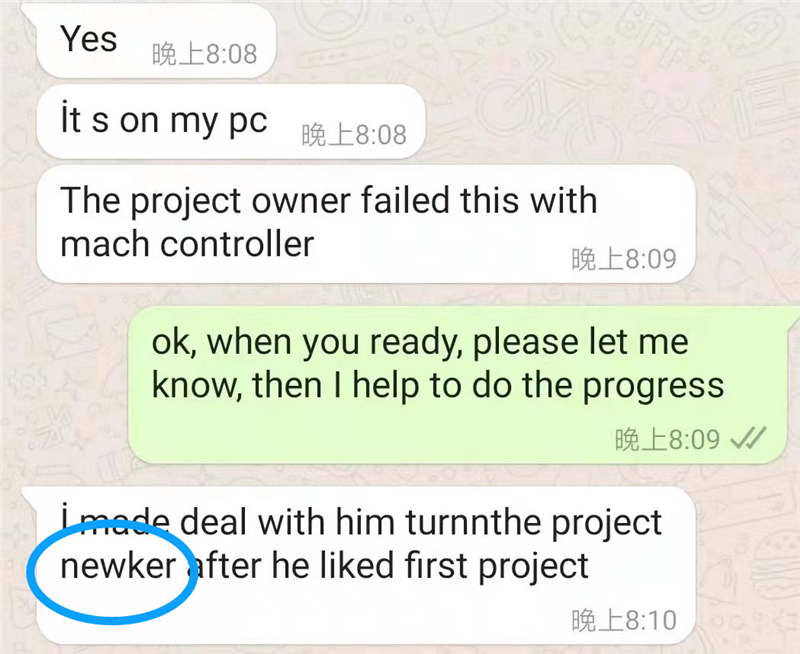

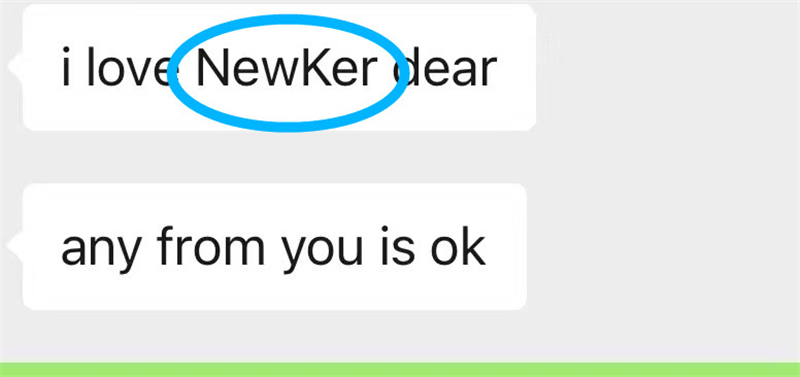

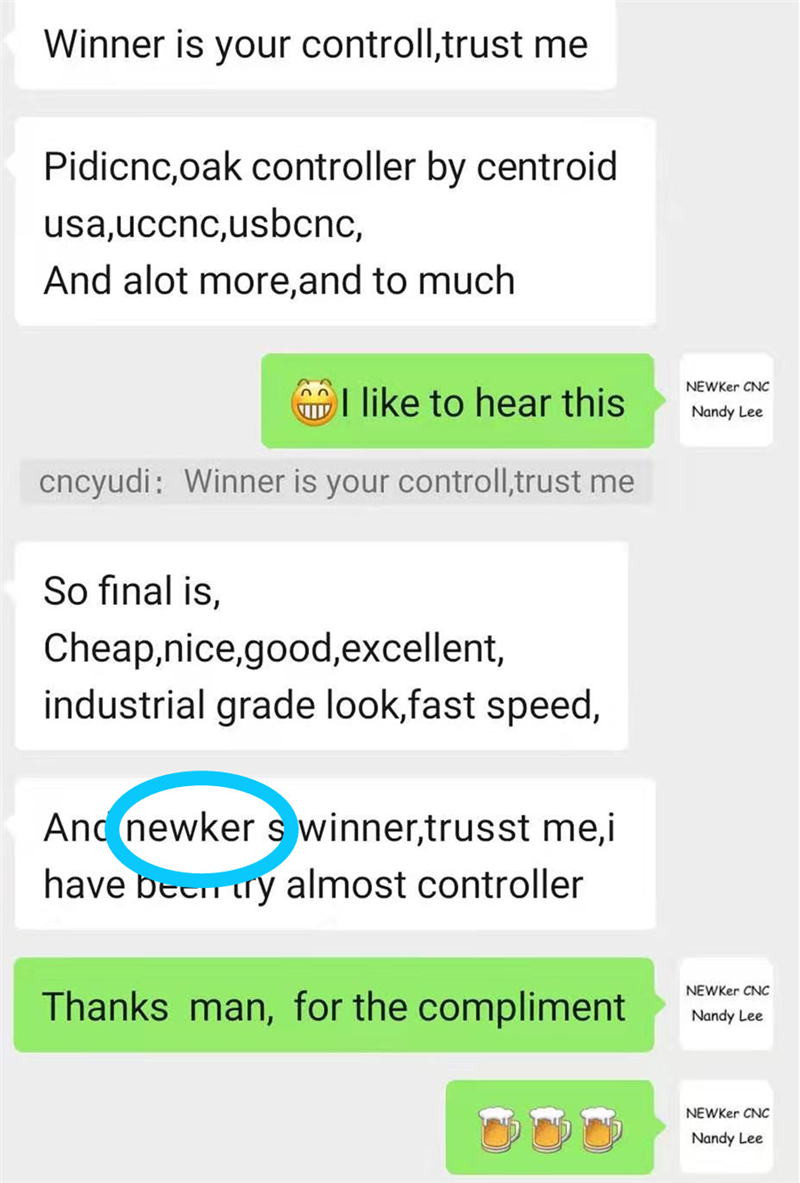

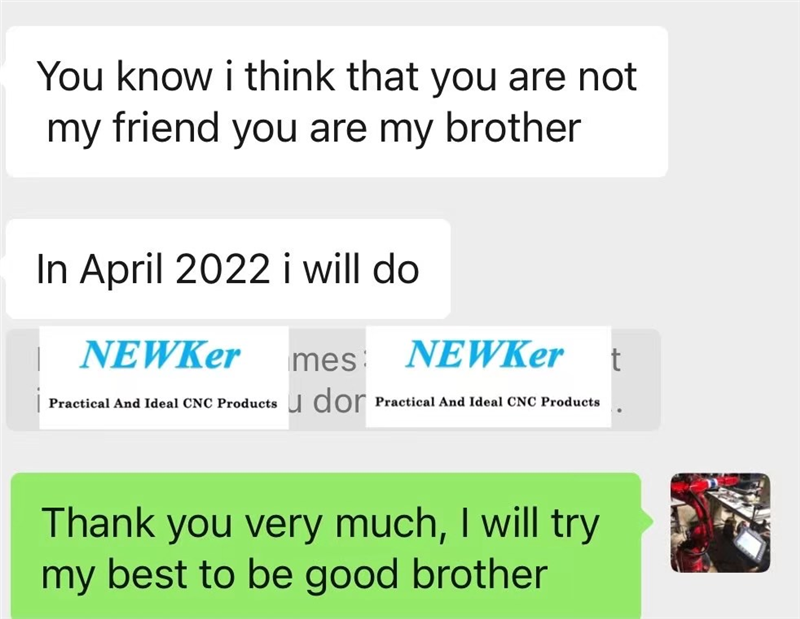

Customer Praise

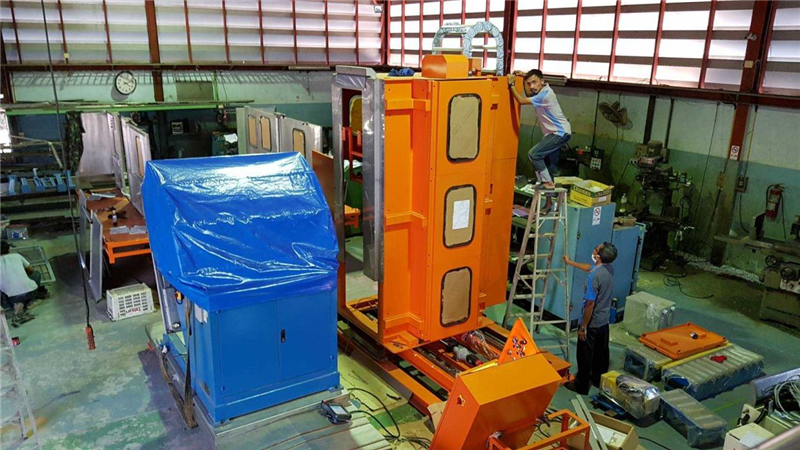

Customer Case